What Does

Borehole Slotting Mean?

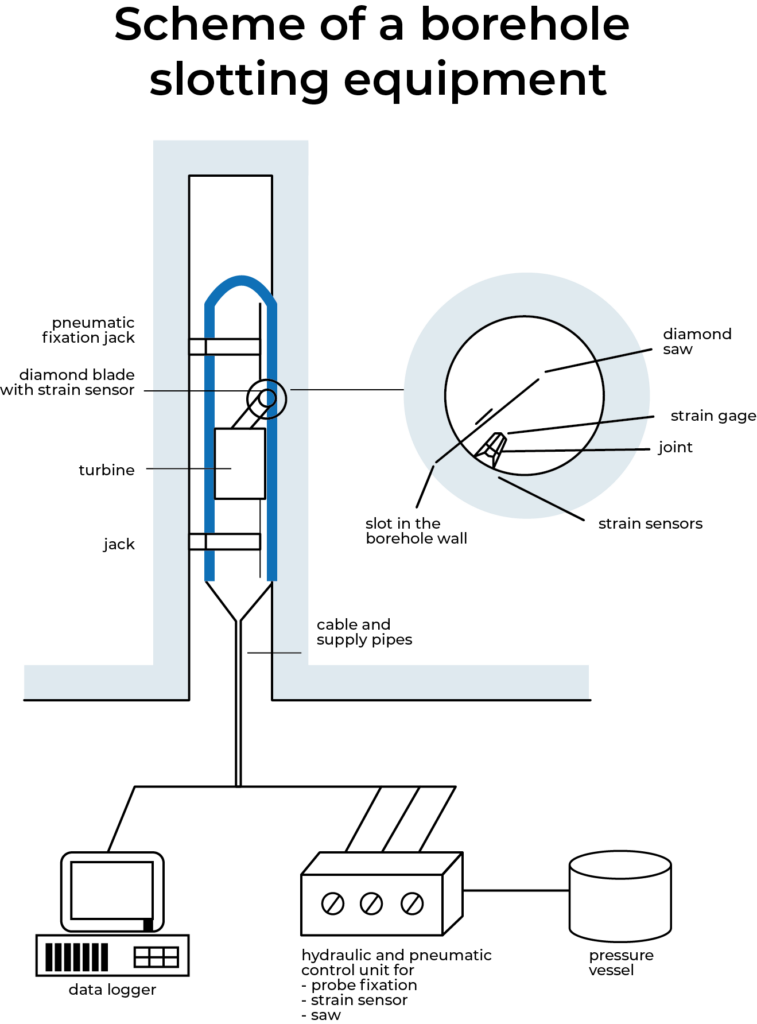

Borehole slotting is a 2-D stress measurement method for in-situ stress in a borehole based on the principle of local stress relief. The method involves sawing relief slots parallel to the borehole axis. The method is cost-effective and is designed for quick operation in boreholes for high-density measurements. The equipment can be fully recovered.

The borehole slotting method has been developed to overcome problems with overcoring and hydraulic fracturing. Some common problems include high cost, limitations of a 2-D stress measurement, and propagation of hydrofracs and borehole wall fractures where the borehole axis and the principal in-situ stress direction do not coincide.

In the borehole slotting method, using a pneumatically driven diamond saw, relief slots about 1 mm wide and up to 20 mm deep are sawed parallel to the borehole axis. A contact strain sensor is pressed next to the slot on the borehole wall with a specific force while slotting is in progress. At least three slots, 120° apart are sawed in different sections in the test location which enable the 2-D stress state to be determined.

At another borehole location, at least 10 cm above or below the first location, three more slotting tests are made. The tested area is considered to be linearly elastic, homogenous, and isotropic. Using the perforated disc model, the primary stress state can be re-calculated using Kirsch’s equation.

Poisson’s ratio and modulus of elasticity must be determined from uniaxial compression tests on cores taken from the borehole for the input values for stress state evaluation.

The borehole slotting method can also be used to determine the 3-D stress state in the rock by conducting the procedure in three boreholes with different azimuth and dip angle.

Trenchlesspedia Explains Borehole Slotting

The borehole slotting method to determine in-situ stress was developed due to some issues in other methods like overcoring, borehole breakout analysis, and hydraulic fracturing. This method is able to avoid many of the inherent problems in the other methods and its equipment is fully recoverable.

Borehole Slotting Principal

Borehole slotting helps determine in-situ stresses in rocks by locally releasing tangential stresses at a borehole surface. This local stress-relief is achieved by cutting a half-moon-shaped radial slot into the wall of the borehole using a small saw impregnated with diamonds. The saw is driven pneumatically while being hydraulically moved against the borehole wall. The slot measures about 1 mm wide and 25 mm deep.

The tangential strain is measured before, during, and after slotting in the immediate area around the slot where there is full stress relief, i.e. within a 15° arc. The measurement is done using a highly sensitive recoverable contact strain sensor, which is a part of the borehole slotter.

The slotting test is done successively with slots in different directions in a borehole. The minimum requirement for a single 2D stress measurement is three slots, 120° apart. However, three more slots are cut 100 mm away from the first three slots. It is also possible to cut additional slots if there is insufficient internal consistency.

Advantages of Borehole Slotting

- Provision for on the spot adjustments.

- Quick testing with time span for one slot being approximately 4 minutes; half an hour for a complete 2D measurement.

- Self-sufficient when externally supplied with compressed air.

- No need for a dedicated drill rig.

- Both geological and geotechnical stress fields can be evaluated in detail.