What Does

Hoop Stress Mean?

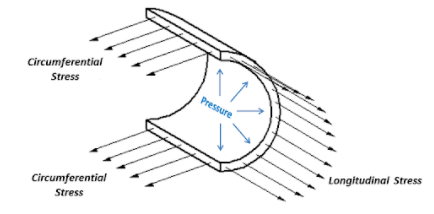

Hoop stress is the stress that occurs along the pipe’s circumference when pressure is applied. Hoop stress acts perpendicular to the axial direction. Hoop stresses are tensile and generated to resist the bursting effect that results from the application of pressure.

Three principal stresses emerge when the cylinder ends are closed and the pipe subjected to internal pressure, hoop stress, longitudinal stress, L and radial stress, r. In thin-walled pipes or pipes with a wall thickness equal to or less than the diameter, d, divided by 20, the radial stress is negligible.

Figure 1: Hoop Stress & Longitudinal Stress in a Pipe under Pressure

The hoop stress increases the pipe’s diameter, whereas the longitudinal stress increases with the pipe’s length. The hoop stress generated when a cylinder is under internal pressure is twice that of the longitudinal stress.

Longitudinal joints of a pipe carry twice as much stress compared to circumferential joints. As pressure is uniformly applied in a piping system, the hoop stress is uniform in any given length of pipe.

Hoop stress is also referred to as tangential stress or circumferential stress.

Trenchlesspedia Explains Hoop Stress

The mode of failure in pipes is dominated by the magnitude of stresses in the pipe. If there is a failure by fracture, it means that the hoop stress is the dominant principle stress, and there are no other external loads present.

Failure due to hoop stress can result in the pipe splitting into two halves or rupturing perpendicular to maximum stress. Bursting of the pipe occurs if the force created by the internal pressure exceeds the hoop stress’s resisting force.

In the design process, pipe stresses are appropriately analyzed, as extreme failure can result in loss of property or life and environmental harm. Analysis of hoop and other stresses also increases the pipe’s longevity and is warranted when there are sensitive equipment connections, the presence of external pressure, and elevated temperatures. Inspections, hand calculations, or computer modeling are methods of analyzing pipe stresses.

Calculation of Hoop Stress

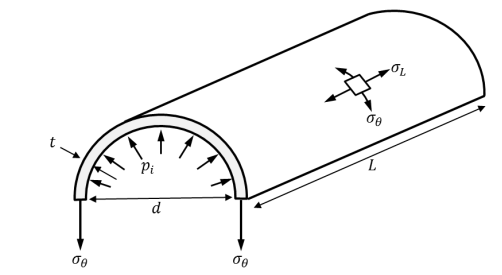

Hoop stress is a function of the pipe’s diameter and wall thickness, the magnitude of which changes as these dimensions vary. Hoop stresses separate the top and bottom halves of the cylinder. Its calculation considers the total force on half of the thin-walled cylinder, due to internal pressure.

|

Hoop Stress

|

|

pi

|

Pressure

|

|

d

|

Cylinder Diameter

|

|

L

|

Cylinder Length

|

|

t

|

Cylinder Thickness

|

Figure 2: Parameters Used to Calculate Hoop Stress

The bursting force acting on half the cylinder is found by the product of the pressure and the area.

FB= pi ×d ×L

The resisting force resulting from the hoop stress is a product of the resisting area and the hoop stress.

FR= 2t×L ×

Under equilibrium, the bursting force is equal to the resisting force.

pidL=2tL

Therefore, the hoop stress acting on the wall thickness, = pid2t