Cast iron pipes have been a staple of city infrastructure since the 19th century. The metal is a durable choice that was a significant improvement over the previous system. While these pipelines can last for over a hundred years, over time, they are susceptible to corrosion. Bacteria found in water and waste can eat away at the interior walls causing tuberculation in the lines.

What is Tuberculation?

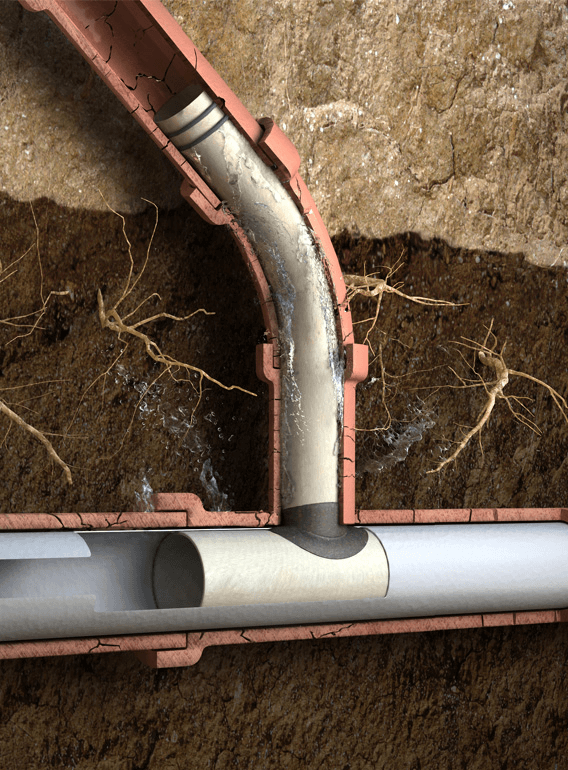

Tuberculation forms along the pipe wall due to iron-oxidizing bacteria found in the water. The bacteria congregate in water lines and begin to metabolize the cast iron pipes. The brown slime builds up and coats the interior of the pipe. While the loss of water pressure is an indicator that there is a build-up of some form in the line, a primary sign of tuberculation is pitting found along with the interior of the pipeline. The build-up can be seen with a pipe crawling camera.

Image source: Trenchless Technology

Image source: Trenchless Technology

As the average homeowner doesn’t have access to a pipe crawling camera, they can tell if there is build-up by the red or reddish-brown staining on plumbing fixtures. There may be some staining on laundry, or water may appear dirty from the sludge building up in the line. If left untreated, the tuberculation can weaken the line to the point of breakage. (Read: Methods for Preventing Corrosion in Infrastructure.)

Is Tuberculation in Your Pipes?

When tuberculation occurs in pipes, it can restrict the flow of water through the line and create sediment deposits and deplete chlorine. A biofilm can also form due to the bacteria eating away at the cast iron of the pipes.

A first indicator that there is an issue is often water discoloration. The sediment in the lines begins to break off and make the water look red or brown. The water pressure becomes affected due to the build-up within the pipe, reducing the hydraulic performance of the lines.

While the flow reduction is visible to consumers using the liens, hydraulic engineers can calculate head losses and flow using the Hazen-Williams formula. The following formula can help engineers to determine the degree a pipeline is constricted, and if cleaning and repair methods are successful.

V=kCR0.63S0.54

Where:

V=velocity, f/sec( m/sec)

K=conversion factor

R=hydraulic radius, ft(m), which is the cross-sectional

C=Hazen-Williams roughness coefficient

S=Slope of the hydraulic grade line, ft/ft (m/m)

As C is the measure of the roughness of the interior of the pipe. The roughness is calculated as:

C=2,466QD-2.63H0.54L0.54

C= Hazen-Williams roughness coefficient

Q= Quantity of flow in a pressure conduit, mgd (m3/d)

D= nominal diameter of the pipe, in. (mm)

H= head loss, ft (m) of water

L= length of pipe, ft (m)

The Hazen-Williams equations are only valid when the water is at an ambient temperature of 40°F to 75°F (4.4°C to 23.8°C) and have turbulent flow. By using the equation to measure the changes between two points along the line, engineers can determine where and how badly a line is constricted.

Of course, equations can only give a calculation of how badly the line is clogged. Being able to see the blockage can help engineers assess if cleaning and repairing are necessary or if they need to replace the line. The use of robots that crawl the line and relay images back to the controller allows engineers to make the best determination on how to move forward. (Read: Trenchless Sewer Cleaning and Repair 101.)

Cleaning Tuberculation in Pipes

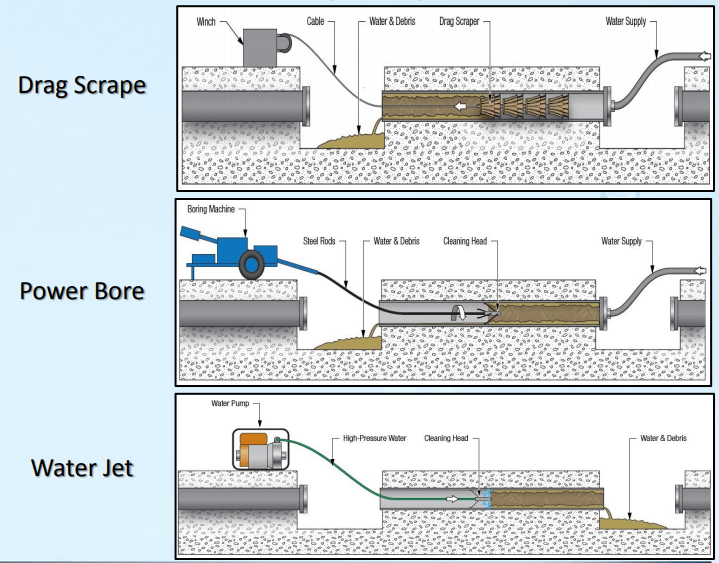

Clearing the pipes depends on the level of infiltration by tuberculation. According to the American Water Works Association Manual M28, there are several options to clean the line of growth. One step is the use of a water jet, also known as abrasive jetting machinery, to remove the slime from the walls. This is low-pressure water jet as high-powered washers or hydro-jetting may soften the surface further, causing cracks where there previously weren’t any.

Another option is the power boring technique. With this technique, a boring machine with steel rods and a cleaning head scrape the sides of the pipe. At the opposite end of the pipeline, a water supply drives water through the line to flush out the debris.

Image source: Brian Thorogood P.Eng

Image source: Brian Thorogood P.Eng

Similarly, there is a drag scrape cleaning method. Like with the power board, a winch with a cable and drag scraper head pulls through the pipe. A water supply pushes the debris out of the line as the scraping head clears the line.

Environlogics Engineering Inc created the Tomahawk System, which clears the tuberculation from the lines while drying the lines out at the same time. This method uses abrasives and a high-volume, low-pressure airstream to clean the pipelines. It is considered an all-in-one cleaning, drying, and inspection system. The system has been used in St. John’s New Brunswick on 780 m of structurally sound cast iron pipe initially installed in 1955. The Tomahawk system, which has been available since 2014, offers a cleaning method that uses little to no water-reducing waste and quicker drying time.

Repairing Pipes after Clearing Tuberculation

Once the tuberculation is clear, engineers need to repair the pipe to keep blockages from occurring again. The most common way is to line the pipe. Depending on the level of corrosion, different types of lining are utilized.

For municipalities looking for a modest hydraulic improvement once the line is clean can use a loose sliplining. Those looking for a moderate hydraulic increase close-fit sliplining, cured-in-place lining (CIPP,)or epoxy lining are a better choice. The lining will keep the tuberculation from reappearing. (Read: A Look at CIPP and Aging Drinking Water Infrastructure.)

Liners are considered nonstructural improvement methods. Nonstructural improvement options are appropriate for pipes that suffer from minor deterioration. However, lines with significant external corrosion will not benefit from the use of any type of liner.

Image source: LMK Technologies

Image source: LMK Technologies

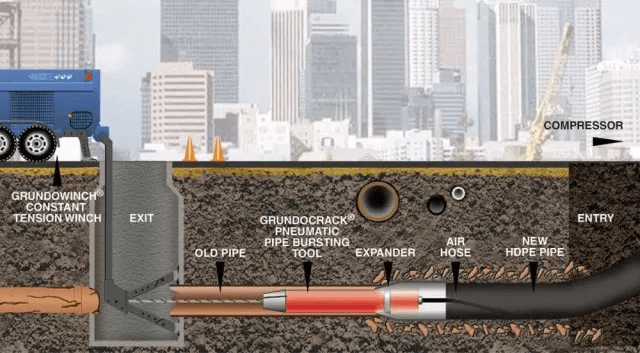

If the line is significantly damaged, or the municipality wants to greatly improve their hydraulic flow, replacing the line might be the only option. To replace the line without digging it up, engineers use a technique known as pipe bursting. With this method, a bursting head is dragged through the existing line breaking it up. The new pipeline attaches to the back of the bursting head and is pulled into place.

Image source: Western Rooter

Image source: Western Rooter

Conclusion

Tuberculation is common in older cast iron pipes. While they may be over 100 years old, cleaning and lining these lines can help to keep them in working condition. If replacing the pipes can be avoided, pipelining is a viable option. New pipe liners create a coating between the cast iron and water that can keep the bacteria from eating away at the walls damaging them to the point of no repair.