This article covers an overview of trenchless pipe installation methodology, called pipe bursting. It includes aspects in the design consideration, review of effect to the surrounding environment, as well as discussion on the construction cost.

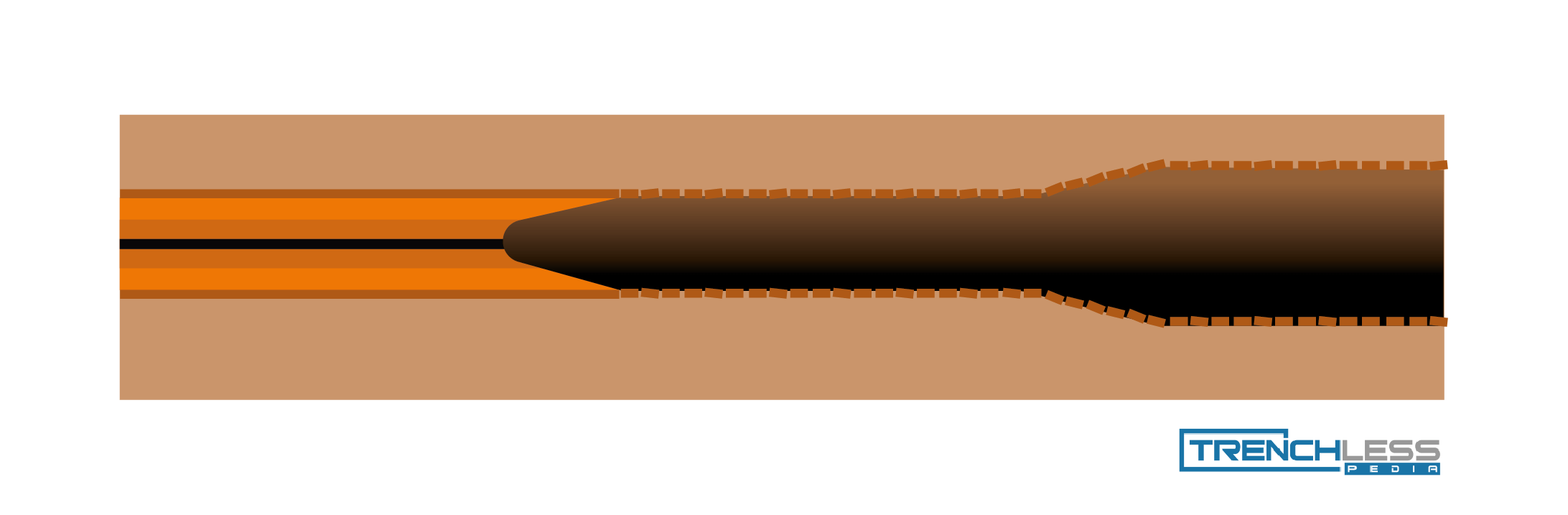

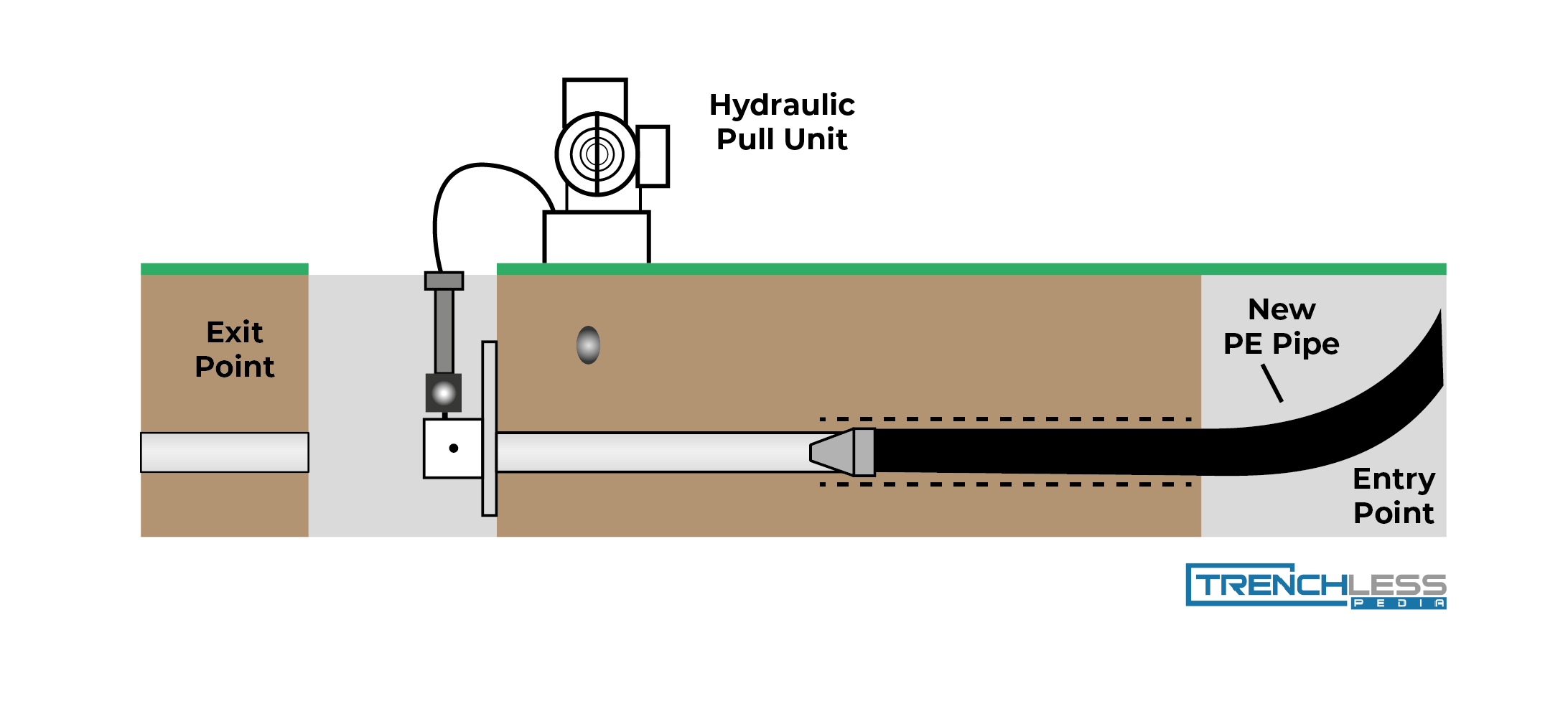

Pipe bursting is a process of pipe replacement by pulling a new pipe—typically, High Density Polyethylene pipe (HDPE)—through an existing pipe. The existing pipe will be shattered and broken by the bursting head during the pull. The surrounding soil will also be pushed away. This creates room for installing the new pipe. Two types of pipe bursting: Pneumatic, as shown in Figure 1, and Hydraulic/ Static system, as shown in Figure 2. (Read also: Understanding the Differences Between Pneumatic and Static/Hydraulic Pipe Bursting.)

Figure 1: Pneumatic pipe bursting employs a guided cable and bursting tool head driven by compressed air. The method is discrete, similar to a pile driving method.

Figure 1: Pneumatic pipe bursting employs a guided cable and bursting tool head driven by compressed air. The method is discrete, similar to a pile driving method.

Figure 2: Static pipe burst system typically employs a larger tensile force. The pulling force is exerted by a hydraulic unit located on the ground.

Figure 2: Static pipe burst system typically employs a larger tensile force. The pulling force is exerted by a hydraulic unit located on the ground.

Design considerations include site conditions, which must be assessed through an investigation, determination of shaft locations, and the survey.

Site investigation is essential prior to the pipe bursting. It includes an assessment of the host pipe, site conditions, and underlying subsurface characteristics. This would determine the selection of locations for the launch pit and pulling shafts, staging area for fused pipe, traffic control, and footprint for the needed bursting system components.

A geotechnical investigation is needed to assist the contractor in selecting the proper pipe bursting method. The subsurface investigation includes test soil bores, standard penetration tests, and groundwater level assessment. It also helps determine the design of trench geometry and backfill materials.

Pipe bursting typically requires the soil surrounding the pipe be compressible to be able to retrieve the pipe expansion. Less favorable soil conditions for the bursting are densely compacted soils, submerged soils, and expandable soils.

A high groundwater table with the site below the water table would require constant dewatering. Highly expansive soils or collapsible soils would also be not desired; therefore it should be avoided in the excavation and a more suitable site located. (Read also: When Ground Improvement is Needed During Trenchless Rehabilitation.)

The contractor will dictate the means and methods of pipe bursting. It is typically preferred that the shaft locations be at distinct pipeline appurtenances or infrastructures, such as manholes, valves, lateral connections, or fittings, that require replacement.

Survey tools such as Ground Penetrating Radar (GPR) may be required to determine the presence of washouts or voids in the subsurface. Assessing the presence of rock, hard cemented dense soils, very soft or loose soils, and contaminated soils should also be undertaken to understand the site as well as possible. These conditions could negatively impact the pipe bursting if overlooked.

The effect of pipe bursting on the surrounding environment includes ground displacement, noise, vibration, and impact to nearby existing utilities. (Read also: Trenchless and the Environment: How No-Dig Construction Saves Eco-Systems.)

The amount of ground displacement is related to the degree of pipe upsizing, the type and density of the existing soil surrounding the host pipe. Cohesive soils tend to displace in a more predictable manner. Loose soil such as sand can locally collapse.

Noise during a pipe bursting operation typically comes from the air compressor used in the machine. This noise is typical to any construction activity as air compressors are utilized on most construction sites.

Ground vibrations can be quite perceptible to a person standing on the surface adjacent to the pipe bursting. Nonetheless, the vibrations are unlikely to be harmful unless to sensitive structures located very close to the operation.

Typically, any pipe infrastructure within 1 foot from the host pipe will be impacted or damaged. Existing pipes in the area nearby within 2 pipe diameter of the host pipe would be exposed or daylighted to release any external pressure imposed. Physical site prelocation is also critical to properly identify existing pipe locations.

The cost estimate of pipe bursting plays a key role when determining construction technique. The unit rate of pipe bursting can be lower than the traditional open-cut method in unfavorable site conditions or in more than 10-ft depth in favorable conditions. Pipe bursting offers a reduction in the construction costs because it requires less excavation, less backfill material, less machinery and a smaller labor force.

A smaller footprint of the site, less impact to the existing traffic, lower carbon emission, and quicker installation are also advantages of the pipe bursting method that would reduce overall construction cost. The construction cost is driven by good judgment of shaft location selection, implementation of proper technique, and thorough site investigation.

Another advantage of the pipe bursting technique is the ability to use as a lining mechanism with potential to upsize the host pipe. Few sample cases where pipe bursting is deemed a suitable approach are:

- There are only few numbers of lateral connections to the host pipe where reconnections are required within a replacement section.

- The host pipe is no longer in a structurally sound condition or has lost its structural integrity.

- Additional pipe capacity is desired.

Conclusion

In summary, using pipe bursting is an important method in the trenchless industry. It allows pipe replacement or upsizing of the existing/ host pipe with minimal excavations. Pipe bursting design considerations discussed above are

- Site reconnaissance/ review existing pipe and site.

- Selection for shaft locations.

- Assessment of soil conditions (including geotechnical investigation and GPR survey).

Typical effects on surrounding environment from the pipe bursting operation are:

- Ground displacement.

- Noise and vibration.

- Impact on nearby existing utilities.

Pipe bursting is the preferred construction method where it is properly implemented and as a result, drives the construction cost lower than the traditional open-cut method. Design and site conditions are the key factors.