Drilling fluid mistakes are common in trenchless construction. Often, these mistakes are made to save money. However, these cost-cutting techniques can cost companies more money eventually. Without adequate drilling mud, boreholes may become less stable, drill bits and rods may overheat, and damage to the equipment is inevitable. To better complete the drilling project, it is best to avoid these top drilling fluid mistakes.

Inadequate Flow Rate

To properly maintain drilling equipment, there needs to be an adequate flow of drilling fluid through the system. In fact, the slurry flow rate and drilling speed require precise calculations.

The exact calculation of slurry flow through the rig depends on an array of variables. Each slurry pump requires a slightly different ratio of solid to liquid, but the calculations remain the same. Check with the manufacturer’s requirements for the exact ratio before beginning.

To calculate the exact slurry flow rate, find the specific gravity of the slurry along with the concentration percentage of solid to liquid in your slurry.

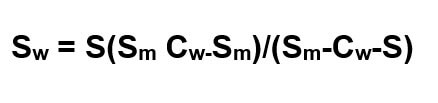

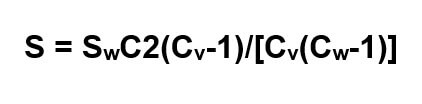

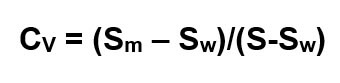

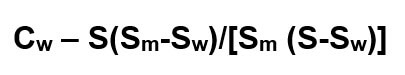

Sw = Specific gravity of the liquid

S = Specific gravity of solid

Sm= Specific gravity of both the liquid and solid

Cv = Concentration of solids in slurry by true volume (a percentage)

CW = Concentration of solids in the slurry by true weight (a percentage)

The specific gravity of the liquid can be calculated by:

The specific gravity of the solid is calculated by:

To calculate the concentration of solids in the slurry by true volume:

To calculate the concentration of solids in the slurry by true weight use the calculation:

Using the instruction manual and the above equation set, workers can correctly calculate the slurry flow rate necessary to keep the drill and pumps operating at optimal efficiency.

Read: Mixing Mud: The Science of Drilling Fluid in HDD

Failure to Accurately Calculate Water and Additive Ratio

Some drilling companies believe that water is enough to act as a cooling agent for their drills. Water does make up approximately 95% or more of the slurry mixture. However, the lack of additives can be harmful to the drilling process. Not only does water not adequately cool the drill, but it also doesn’t help to stabilize the bore hole or cool the sonde housing like water mixed with the proper additives.

Leaving additives out of the mud is only one error made when cutting corners to save a little money. Sometimes, workers inaccurately calculate the additive-to-water ratio. Several variables go into determining how much additives should be added to the water to get the appropriate mixture.

For example, the proper ratio of mud with the weight of 11.0 parts per gallon may be 30 parts per billion (ppb) of bentonite, 5 ppb CMC polymer, 5 ppb caustic soda, 25 ppb of Na2CO3. Adding too much or too little additives could cause drill or borehole failure.

Read: Bentonite and the Use of Drilling Mud in Trenchless Projects

Inappropriate Mix Makeup

While an incorrect additive ratio is one mistake, inappropriate mix makeup is another. Other drilling fluid mistakes that occur with the wrong mixture include a mismatching of drilling fluid for the soil, not testing the water quality before mixing and combining the additives in the wrong order.

Mismatching Drilling Fluid and Soil

Different soil types require a different mixture of additives and water. For example, soils consisting heavily of clay benefit from PHPA polymers instead of using bentonite. The PHPA polymers help to prevent the clay in the ground from swelling and causing issues with borehole integrity.

Areas with more sandy conditions need the addition of bentonite to the drilling fluid. Bentonite helps to provide filtration control, while areas with rocky soil benefit from a larger, heavier molecular polymer. The larger polymer size acts as a suspension agent to stabilize the borehole.

Proper soil testing gives you the makeup of the ground in the area where drilling is to occur. Consulting the drill manual will help to ensure mud mixers create a drilling fluid mix appropriate to the soil structure involved.

Not Testing Water Quality

Water quality affects the overall mud mixture. Water with an improper pH balance or imperfections will throw off the ratio of the additives. Before mixing drilling, fluid workers should test a sample of the water for quality. If poor water quality occurs, it can be counteracted by adding soda ash to bring it to the right pH levels.

Flushing the lines before filling the mixing tanks with water also helps to clear out any contamination. Sand may settle into water lines. The sand in the fluid will throw off additive ratios, giving the drilling fluid an improper mixture.

Inadequate Additive Mixing Time

Some additives take longer to combine with the water. Using an aggressive pumping action to create the solution does help to create the homogeneous mixture needed for proper drilling fluid. Workers should combine solvents that require a higher shear mixing for proper dispersal before adding substrates that don’t take as long to combine.

Workers should also combine additives in small ratios and mix thoroughly before adding more to the solution. If the designated mud man does not adequately blend the drilling fluid, issues may occur during the bore. These issues include the drill bit not being cooled sufficiently, cuttings settling into the hole and seizing the bit, or high fluid loss through porous materials.

Reclamation Failure

All drilling fluid must undergo a reclamation process. Failure to do so is a mistake that can be costly to the drilling company and hazardous to the environment.

Because most drilling mud has an array of additives combined with water to help shore up the borehole, transport out cuttings and cool the drilling equipment, most companies use above-ground recirculating/recycling systems.

The recirculating system removes all the cuttings while keeping much of the drilling fluid in the system. Allowing fluid mixtures to soak into the environment can be dangerous and potentially contaminate the groundwater.

To remove solid materials from the reclaimed drill fluid, shale shakers or desanding/desilting cones separate the waste. These solid chucks are sent down chutes on the back or sides of the equipment, and the “cleaned” fluid drops into tanks underneath.

If the reclamation systems are not adequately maintained, solid waste can remain in the fluid, making it inadequate for continued use. Leaks in the network can cause the mud to soak into the ground, causing contamination.

Proper Planning Is Key

With proper maintenance and planning, workers can avoid each of these drilling fluid mistakes. It is essential for the safety of the crew, environment and equipment that engineers take the time to plan the project properly. Using a designated mud man is advisable.